Have you got one of these on your farm? Is it time for a change?

If you’ve got an aerator sand filter on your farm, then you’ll be familiar with manual back washing and regular change out of the media.

The aeration process oxidises the soluble iron (Fe) in the bore or ground water, turning it to rust. These rust particles are then filtered through the sand bed.

Over the course of the day, they build up, reducing water flow and indicating the filter needs to be back washed.

The sand filter doesn’t do much for the Manganese though!!

So, you’ll also be familiar with this – manganese build up in your pipe work.

Spending a lot of time out in the field, we see the challenges farmers must contend with.

At one farm, the farm owner had to replace a $5,000 mineral dispenser due to manganese build up.

Another farmer had to replace 250m of alkathene pipeline due to it being plugged with manganese deposits – even compressed air cleaning couldn’t save the pipeline.

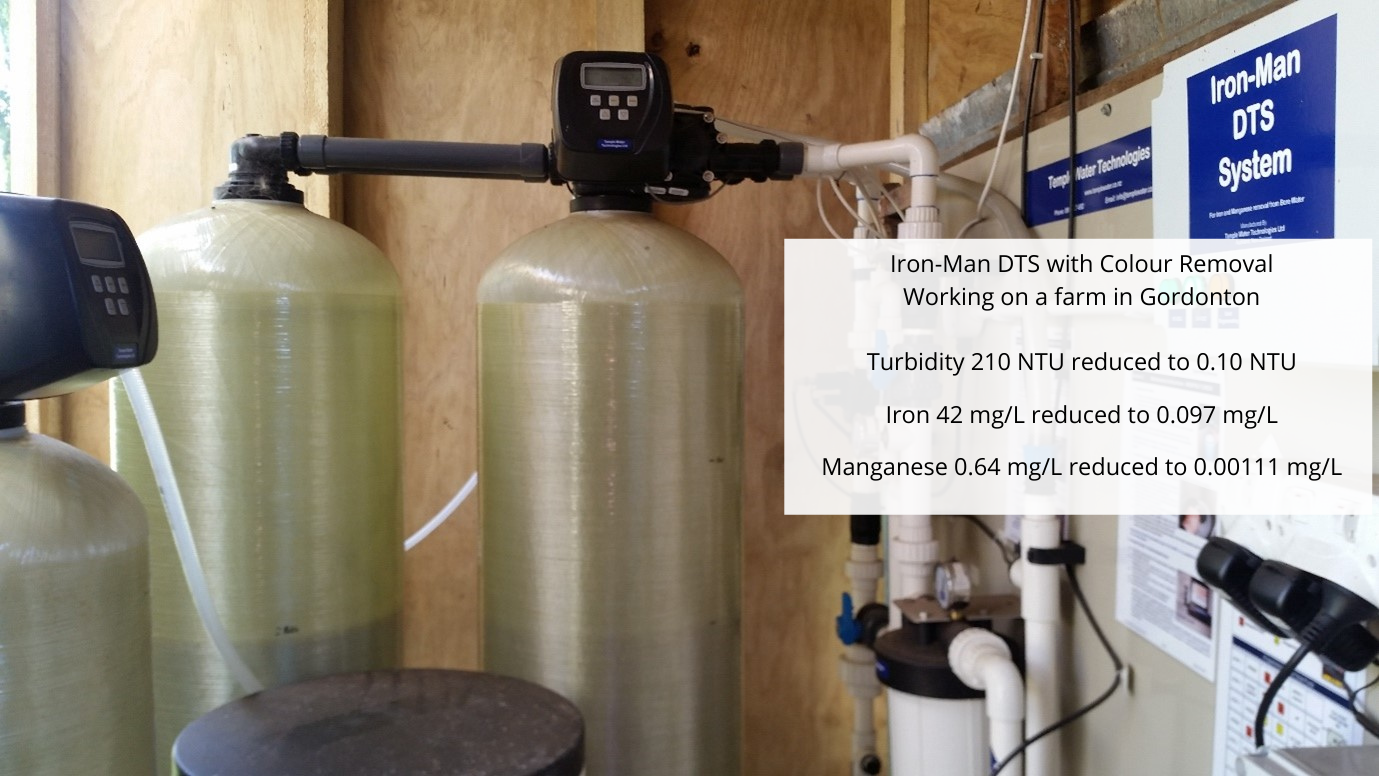

If you’re ready for a change, Temple Water Technologies Iron-Man Range will have a solution that will suit the specific needs, you have on your farm.

Temple Water recognises busy farmers today and automates the treatment process eliminating labour input by either the farmer or staff.

“We understand today’s farmer has lots of modern technologies on the farm and actively seeks out labour saving technologies that improves time and labour input and provides consistent results.” says Chris Temple.

The team at Temple Water caution today’s farmers from investing in technologies quoted over the telephone or based on water analysis alone without a site visit.

Our proven process of water analysis and site testing on the farm allows us to lay claim to the fact that all our treatment systems installed, even as long as twenty years ago, are still working today producing clean, clear, quality water.

Temple Water Technologies Iron-Man Range